Posted on

May 17, 2010 by

bp complaints

New Deepwater Horizon images:

ROV attempting to activate Deepwater Horizon Blowout Preventer

Image by uscgd8

100421-G-XXXXL-_003_-_Deepwater_Horizon_fire

Image by uscgd8

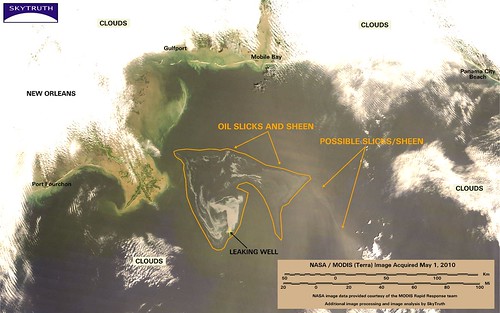

Deepwater Horizon Oil Spill – MODIS/Terra Detail (with interpretation), May 1, 2010

Image by SkyTruth

Tags: Activate, attempting, blowout, Deepwater, Horizon, preventer

Category

News

Trackback: trackback from your own site.

Hodyz

You just won’t give up will you. The main kink is below the riser, where the equipment is rated to full shut-in presse. That’s why it doesn’t nothing blows up. I don’t mind that people are bringing "stupid" questions to the table and get answers, but when people are as ignorant as you and just don’t give up their 101 fluid dynamics course, that’s when it gets silly. Your dynamics, energy balance and whatever else you’ve been bringing to the table does not mean anything. All you neeed to know is the well head shut in pressure (no flow) and whatever the riser is rated to. If the riser is rated below this pressure, it will burst. Right now, nowbody here knows the well head shut-in pressure.

My email:

MDavis@DrillScience.com

if anyone wants to correspond directly with me on their thoughts, feel free. If there are any non mechanical types that need to know and would be helped by contacting me and talked with in laymen terms as well, feel free. My parents aren’t technical yet very smart. They call me anytime they see news of oil industry. I have a sense of responsibility to public and obliged to help every way I am able.

Yes the setup you describe is usually in most fitter shop tool inventory. usually called a hot tap. a fitting with a valve is attached to the pipe. the tool is designed to bore through the pipe, through the opened valve/ the boring tool retracted and the valve closed. tap made. I`m sure you know that and that is what you are describing. but can the rov do this type of operation? That is my question. I am not familiar with that BOP but I have never seen a piece of equipment like that designed in a manner that did not have some type of clean out or inspection/service port built in. I hope that is the case here.

First comment here.

Thanks, Horizon37, I get what you’re saying, even though I’m a layman with a Bachelor of Arts degree (I was a Technical Writer, though).

We’ve got a BOP that has probably partially deployed, but is being prevented from completing the shear/seal by debris in the drill pipe, ala Ixtoc in 1979. At that point, inside the BOP, we probably have a partially crushed pipe with crap in it.

That is the main flow restriction in the well, and where the main pressure drop is occurring. The open cross section of the drill pipe, with its several openings, is plenty to allow the estimated 200K+ gallons of oil/gas per day to exit. 200K gallons per day works out at about 5 gallons per second. Given the size of the drill pipe, that ain’t much, even with the kinks involved. A 4 inch firehose makes a joke of that flow rate using simple hydrant pressure.

I suspect BP knows its well pressures, and if this blowout could be safely capped with an ROV and a vise, they would have done it (I confess to having entertained that idea early in this crisis myself).

If there is a simple, effective solution, then there is usually also a good reason why experienced engineers don’t employ it. I’m sure they’ve heard numerous proposals for capping the riser so far.

For you experts — Would it be possible to emulsify the oil with air at depth to change its density to cause it to rise faster and reduce the surface area where it reaches the surface? Might also make it easier to collect.

You people must understand what a crimp in a line does, and how it is different than what horizon says. The implications of horizons statement is this. When a pressure gradient is introduced across a crimp, pressure on one side will continue to increase until it equalizes with the pressure in the reservoir. That is a direct challenge to energy minimization and he has yet to provide a professional reputable reference backing his statements up. I’m not the one at war with thermodynamics. I have nothing to prove. If he is going to try to disprove the laws of thermo, then I expect to see a professionally referenced response and not a bunch of blather. Let me just ask you, why should I believe a word you are saying? Are you the one who makes up the thermodynamic rules? It is very difficult to deal with some so childish and unprofessional who is so conceited, as to think he doesn’t have to prove a word he says because his word is the word of god. Go back to preschool man, you have no business being an engineer if you can’t act like one. Show me experimental proof that crimping in pipe reduces flow rate. Surely you must have some source for your information. It is not for me to prove to you that I’m right, it is for you to prove to me that you are right. In the mean time, quit trying to sell me a bridge in Brooklyn.

Guys, please ignore hoodyz’s comments for the nonsense they are. Let’s continue the meaningful dialogue that took place above when he took a break.

"Show me experimental proof that crimping in pipe reduces flow rate. "

Dude.

Every bend a garden hose? Notice what happens? Flow slows down and eventually cuts off.

Garden hose gets harder and harder above the crimp. Even swells a bit.

Go perform the experiment outside right now. It’s always worked the 1000 or so times I’ve done it.

Send your idea to BP’s engineers. There is a link on this site to do so (no, I’m not going to find it for you). They’ll evaluate it–they’ve already done some things (like piping dispersant down directly to the leak sources) that are new.

But also accept perhaps that there is a good reason they might not use your idea.

Please explain under normal operating condition, how is that well pressure of 5K or 20K is reduced all the way down to 500 Psi before it is sent up the riser pipe? My understanding is that Riser pipes are designed for maximum 500 Psi although the BOP and other wellhead components (casing hanger and casings) are designed to withstand much higher pressure.

PetroleumEngineer1,

The coil tubing needs a guide conduit, or you can’t "push" it down.

Coil tubing is not quite like drill pipe, it has very little weight of its own to mill things, I have used it many times to mill cement out of drill pipe after a flash set on a cement job.

It has been my experience that, cementing through 1" coil tubing is an invitation to disaster, the ID is just too small to allow an effective pump rate, also the small ID has a tendency to bridge off, kind of like doing a squeeze job through a 12,000 foot perforation.

The biggest problem I see in trying your idea is that the cement, as you know, is way heavier than the oil and it will just settle to the bottom of the well instead of building up a plug in the BOPS or below them. However having said that it might be possible to use an 1-1/4" tubing reel, and place foamed cement in the well a few thousand feet below the BOPs, but it would have to be very fast set, and most likely they would end up with a bunch of cemented up coil tubing in the hole & BOPs. But this has problems as well, because the oil is moving up the hole at 50 ft/min it will be very difficult to get a viable plug.

Any milling on the riser would make me very nervous, it’s already in a huge mechanical bind and and could be holding back well head pressure at the kink, and if a hole is punched in it, it may be the straw that broke the camels back and cause a major rupture in the wall, kind of like poking a balloon with a pin.

It also would not surprise me, if the wellhead connection to the 20" is not cracked, as the wellhead was never intended to be abused by having 3 million lbs of riser dropped on it, and pulling it off to the side. It could be that the bent over riser and the 13-3/8" and 9-5/8" wellhead adapters are all that is holding the BOPs on the well.

Might drop lead or graphite beads. Same story need access via top. Can position caisson via subsea intervention lift vessel. Might drop large OD spear with high volume dump bailer, or at least position to dump when debris is pulled away. If shear rams are closed this idea loses merit. Graphite beads work best in that case. Or lead beads. Call your local shotgun shell suppliers. Keep the help flowing; we all seem aware of the urgency and non reversability of this disaster. Need heroes ideas and action now…

Yes. Correct need guide. See previous procedure for lowering tubing guided by multi depth ROV as the guide conduit. Yes. You’re correct. Exactly. Yet your concerns also right. Bravery must equal the fire consequences in balance with potential worsening. Foam cement? Spot on great! Keep this going. I think you’re the guy to figure on a great plan. I will keep helping.

I’ve been following this thread for days and shared it with a friend of mine who is currently captain of a deep water drill ship off the coast of Africa. It has been enlightening to read. Thanks to those in the industry who are very patient with us novices.

I wanted to share a link to a radio interview that my captain friend just shared with me. It is an interview with one of the workers that was on the rig when it blew.

http://www.marklevinshow.com/Article.asp?id=1790422&spid=32364

Also there is much larger OD coil tubing available on these subsea intervention vessels. Talk with Ivar Siem. Owns Siem Industries and Drill Mar. I want to say 2" and above available.

if milling that small of a hole through a set valve could cause the line to rupture like a balloon we are in a lot more trouble than we think. I`m sure it has been engineered with a better safety factor than that. I have wet tapped many high pressure lines while charged while installing and or modifying hydraulic equipment. I would think their maintenance people have the equipment to do that type of tap somewhere. it is a relatively common procedure in industrial maintenance. so I don’t think that would be an issue. whether it has been planned for or practiced for being done at 5000 feet is the only real issue. imho

PetroleumEngineer1,

Yes there are larger coil tubing units, but the problem lies in that the larger the OD of the tubing the less linear feet of it on the reel, it also effects the load the skates on the injector can carry without crushing the tubing. 5,000 ft of water is definitely a challenge.

I would like to add that setting a plug in the BOPs or below them will make the intervention by the relief well even more difficult, because in order to inject kill mud it has to have somewhere to go besides just downwards into the formation, IF they are lucky enough to intersect the old well above wherever it is the flow is coming from. If they are below it, they cant get fluid to flow upwards past the zone unless there is a free path to the seabed to do so.

I would imagine, that is one of the reasons BP is anxious to get a wellhead pressure, using that pressure they can get a pretty good idea of the depth of the zone that is producing within a 1,000ft or so.

does anyone have the model number of this BOP?

another route I will mention, it has most likely been tried and discussed but I will bring it up since I have not seen any talk of this approach. is it possible or feasible to raise the hydraulic pressure and attempt to stroke the rams to get them to fully actuate?

virtually all systems I have dealt with have been greatly over engineered as to actual pressure before failure due to shock stresses and hammer of hydraulic systems. at this point it may well be worth the risk of cranking up the pressure and trying to hammer it closed. exercising the systems may well achieve a seal.

Hammer,

It’s not that your idea is not feasible, it’s the fact that once a hole is cut, it’s irreversible, and if whatever operation you were attempting fails, it’s game over.

In one of my earlier posts I proposed removing a ‘T’ in the choke or kill lines at the isolation valve between the line and the BOP body between the blind rams and lower pipe rams. Then attaching up a hot tap rig to the valve, opening the valve with an ROV then pushing in an abrasive jet cutter or mill to cut the drill pipe and letting it drop, and closing the blind rams. I sent this idea to BP, but there may be reasons they have not looked into it any further, it could be there is not a removable ‘T’ there, I have no way of knowing this without the specific stack drawings, for that stack. Subsea stacks are not standard equipment like they are for land rigs or jack-ups, they are custom built per a drilling contractors specifications. And most of them are different for each rig, although many of the components may all be the same they usually have different layouts.

There are 2 plausible causes for the shear rams not being able to cut the drill pipe, a) there is a tool joint there, that is beyond the capacity of the rams to cut, b) the kink in the riser has the drill pipe jammed off center tin the stack and the rams lack the power or geometry to get the pipe into the cutting zone on the rams. And over pressuring the hydraulics is not a good idea, if they rupture the seals on the ram pistons they may not be able to retract the rams again without installing the hand-wheel, although an ROV can probably install the hand-wheel it’s actuator arm probably doesn’t have the torque to operate it. The hand-wheels are generally only used when working on the stack on the surface when replacing rams.

Cameron type TL 15K according to rig inventory online.

Horizon: good points. Of course trade off with size OD and Length. Can connect two coils I believe yet easier point is that only have to get deeper that the wellhead to do potential good. If the shear rams are partially closed might be easier to plug via choke and kill lines if can attach. If open, then might get coil. Yes, plug will hamper a conventional kill via relief well, yet conventional relief well will be finished after watching two months of Green Peace videos showing Ed Begley crying while washing oily sea gulls with Ivory Soap plastered on every channel and perhaps worse consequences already vivid in all our minds. Human lifestyles completely destroyed for many years and forever. Like you know. Terrible. Simply cut away, and drill out surface/BOPE plug, or junk shot after the relief wells are ready to pump. Thus saving thousands of barrells of spillage for the 90 days awaiting relief well drilling.

Horizon,

the hole is bored into the pipe through an open valve that is attached to the pipe via a steel band clamped around the pipe. the valve can simply be closed and then boring tool removed. the internal pressure of the pipe is the main concern. must have a tool designed for the system pressure. there are many styles and options.

Kenbobb,

ok let’s take your choked flow instance to be true.

I’m not going to address your hose example because that is wrong and irrelavant to what we are dealing with.

Ok. We have choked flow in the BOP right now which was claimed above. Let’s just assume it to be correct. No reason to attack me yet, I’m agreeing with you.

Now this choking in the BOP must be very tight because your wellhead pressure is supposeldy so tremendous. Let’s assume it’s 10000psi like you guys say. Can’t attack me, I’m agreeing with you.

Now with this very tight choke, the choke is not releasing much oil at all. The velocity of oil in your riser is between .05-.1 m/s so very little is getting through your tight choke. With such a small release of oil taking place, the well is already essentially capped inside the BOP. It is acting like a cap because only .05-.1 m/s is making it into the riser above it.

Now think about it. What happens when you cut the riser above the BOP. The flow rate remains the same, after all the choke is in the BOP. So tremendous pressure is built up in the BOP and it is choked very tightly. So cutting the riser above it does nothing to your choke. The flow remains the same. Now put a second BOP on top of that one. This BOP doesn’t have much choking to do because the fluid is moving at only .05-.1 m/s into it. It won’t have to handle nearly the pressure as the first choke in the BOP.

So how’s it gonna blow up? Original choke remains in place. We add a second choke above it. If the BOP was going to blow up due to pressure, it already would have. It’s reducing a tremendous pressure to only a very small flow.

Please be mature and instead of taking the route of instant bashing, read what I just said. It assumes everything you say to be correct.

Horizon,

here is an example of the type system that could possibly be used. watch the videos.

http://www.pipeplug.com/hot_tap_systems.html

A bottom up relief well kill is not thwarted by a surface plug, if despite its obviously dubious viability actually worked. If new BOPE is added on top any surface plug accomplished would be milled up with total well control via top and bottom. Any viable chance of getting a top plug in place should not be halted because of belief that subsequent, bottom kill is thus prevented. That is not true.

Hoodyz

The main flaw in your hypothesis is that you are assuming BP is correct in that the flow is only 210k gal/day through 3 leaks. That figure is a best guess optimistic estimate by BP and does not account for the 4th leak that is estimated at 420k gal/day alone that BP has not released information about yet.

Since you like equations, put the sattelite imagery into a GIS program and assume the sheen is as thin as possible, but also that a reasonable percentage has been vaporized since this is a lighter crude. Do the volume calculations and you will find that they do not match an estimated flow of 5,000 bbl/day.

Hammer,

Ok, your previous post said drill through the valve, I misunderstood your intent.

The part that concerns me most is as stated before, the riser tube is in severe stress right now, and drilling a hole in it may initiate a crack across the stress zone. The outside of that kink in the riser tube is in severe tensile stress, I for one am surprised it didn’t just split open when it bent over at that angle, hats off to VETCO’s engineers.

You may try an experiment, take a rubber hose and kink it like the riser tube, it won’t split open (unless your hose is rotten) but if while you have it kinked over just touch the stressed outside area with a razor blade or sharp knife, it will split open like a watermelon dropped from a 2 story house. And if in our case where there is wellhead pressure at the kink, our small leak just turned into a very large leak.

No no no. .1m/s is what the velocity is for 400k gal/day. No flaw. Still small velocity.

"You are suggesting kink the garden hose a little will affect the flow rate. Theoretically, it can’t. If it did, you are building pressure behind the kink. You can keep building that pressure until either the hose blows up due to the water pressure, or it equalizes with your water pressure and no flow occurs through the kink"

Wow. Even I see the logical fallacy in that.

First, you are ignoring the question of other restrictions on flow. Which there pretty obviously are (most likely is the partially activated rams and whatever crap is keeping them from completing their job).

The garden hose analogy is a spigot (or BOP) that is only partially turned on. Full theoretical flow from the hose would not occur even if it was not kinked at all.

As the hose kinks, at first it is not completely cut off, and while pressure in the hose increases moderately, it still does not achieve well (house) pressure. But it does increase.

Kinking the hose (or riser) over completely results in a rapid increase to spigot pressure, although, from experience I can tell you it is hard to completely stop flow from a simple garden hose by kinking it. The outside edges of the kink tend to stay slightly open. In order to get enough of a flow reduction to allow "hot" replacement of a garden hose sprayer head, I usually employ two kinks. Seriously. I do this pretty often working in the yard.

I think one other thing you are getting hung up on is the question of a little bit of kinking (basically just curving) of a pipe versus an actual kink to 90 degrees or beyond. The restriction of flow will be insignificant as the kink starts, and ramp up rapidly as it proceeds.

But it does not go from unimpeded flow to immediate cutoff. There is going to be a pretty strong resistance to cutting off on the the side of the tube parallel to the kink. Wall pressure at the two edges of the kink are going to resist complete closure pretty fiercely. You can actually see this in the pictures of the kink linked upthread. The kink, rather than being flat, has a sort of a dumbell appearance, where the pipe walls resist complete flattening.

If you don’t see what I’m saying, or think I don’t see your point, I’m afraid you’ll have to give up on me. One of us is incapable of seeing what the other is trying to say.

Besides, in terms of actually getting anything adopted or attempted, I’m worse than useless. I have no oil industry connection, and I’m still working on getting my head around the concepts being expressed here, even as I find myself somewhat unable to express what I’m learning here and elsewhere about deepwater drilling to the general public.

Do the simple calculation for yourself if you don’t believe me. I’m not hiding anything here.

Q=V*A

the riser has a diameter of 18 5/8" as horizon pointed out. Area is a simple calculation after that, as we are only concerned with the unbent portion of the riser above the BOP. That is where all of the oil enters our riser and is after the choke.

You got like .05 m/s for 210k gal/day.

Everytime you double the flow rate, double the velocity.

Do the calculation, look at the velocity. Make sure units match.

Kenbobb, please reread what I rewrote. What I first said was wrong. Yes I was wrong, I’m not too conceited to admit that like some others. But then I realized, following your logic, I could prove that if the choke is in the BOP, anything after the choke is useless to us. You guys suggested the choked flow. You guys suggested the choke in the BOP. You guys suggested the high pressure.

I’m only using what you said.

What is the velocity after the choke in the BOP. If BP is anywhere in the ballpark of 200-400k gal/day, then the velocity is .05-.1 m/s. Surely stacking a second BOP on the first could handle such a small flow and pressure. If the first BOP is choking it so badly right now and hasn’t blown up, then another BOP could handle this small flow.

I mean, the velocity calculation is very simple. I encourage every one of you to do it.

The only assumption made here is that the oil leaving our choke is the same amount entering the ocean. Obviously we don’t have accumulation in our system so it is reasonable. Oil leaving the choke goes into the ocean. Simple enough.

The amount of oil entering the riser above the BOP is the same amount that eventually flows out into the ocean. Nothing changes. Your analysis should be done right above the BOP because that is where we plan on putting the second BOP.

hoodyz,

The riser HAD a flow area of 18-5/8" before it was kinked after it’s kinked it no longer has that same geometry, as a kink progresses CLOSED the flow is decreased until it is zero or it gets to a position, as our riser tube and the flow is merely severely restricted, since the riser is open on the end the pressure will never equalize with the upstream pressure unless the end is capped.

Can any of you calculate the pressure leaving the choke? I’m curious as to what it is. Surely it is very low. The choke is very tight. Not much oil is leaving. If it was not a tight choke, 200k gal/day would be nothing. We would have 1mil gal/day or more. Remember, you guys recommended the choked flow. Don’t bash me for your assumption.

Cutting the riser flowing so slowly with oil isn’t going to affect your choke, remember your assumption. So how much energy does that slow flow have? Surely it can’t be very much. So why can’t a second BOP handle that little amount. I mean, you guys claim these BOPs can handle 15k psi. And the first one handles most of the pressure and it hasn’t blown up. So what makes you think adding a second BOP to shut the tiny flow off will blow the system up.

if there were a crack I`m sure at that pressure it would be leaking. the band for the valve would help strengthen the pipe. then also the best way to stop a crack in metal from traveling is to drill a hole at the end of the crack lol. but I have said enough. I`ll leave things to the experts and go take advantage of my retirement and go fishing while I still can lol. good luck all and have a nice day.

But it was stated the choke is in the BOP. I didn’t suggest that. You guys did. Reread above. It’s up there. The choke isn’t in the riser according to you guys.

And for our velocity calculation, forget everything downstream. We don’t care about it. We care about what is directly after the choke in the riser. That is where we will be adding the new BOP. If the pressure is too high there, it would be impossible, but the flow in that pipe has to be between .05-.1 m/s unless BP is feeding us complete BS and it’s doing 100mil/gal a day which is like 24 m/s. That would be harder to work with.

I have an independent question for Horizon37:

I keep seeing everyone speculate on the causes and everything and you have seemed by far the most knowledgeable. So I was wondering what information you would need to determine what happened on the rig in terms of data that BP would have? If BP was not in CYA mode and they were actually looking for public help, what info would you want? I know everyone wants to see the cement bond logs, but what other pertinent technical data would one need to actually figure this stuff out that they have locked away in Houston?

Sorry if this is slightly off topic from the debate on sealing the well.

"Occasionally an engineer with a lab coat mentality spreads his brand of impractical science and calculation or perhaps worse, performance hindering perfectionism."

Petroleum Engineer1, the spirit of you statement is well intentioned, but you have to appreciate the irony.

A great deal of moderately high technology at impressive scales was deployed in such an amaturish way that it boggles the mind. Imagine for a moment that BP ran nuclear power plants, and used the same safety protocols and did the same contingency planning that they have demonstrated here.

A good engineer doesn’t assume anything. A good engineer knows that things fail, and plans for it accordingly. It is nearly beyond belief that the systems team did not have a proper protocol for the most basic, fundamental failure: the loss of control at depth. The rig blowing up is one thing, as all the workers know the dangers, but it’s another thing entirely when system failure adversely affects millions of unsuspecting people.

Those engineers who sometimes get in the way… those would be the engineers that should have been on the job before that well was ever drilled. BP should pay whatever it takes to place some if its engineers in GE’s jet engine division for a year to get a sense of how grownup engineers work.

As far as corporate goes… I bet all those safety devices it lobbied so hard against being required to install… I bet those devices look pretty cheap about right now.

This is a tough was to learn, but learn we will.

Eloquently put! Bravo DelShady. Diligence is king in business. Yet engineers are employed to build the cheapest structure that won’t fail it’s purpose and survive it’s intended lifespan. Anyone can build the strongest structure possible yet it would cost too much and consist of the strongest materials on earth. Yet, always, the business cost of a disaster must not be decided via the usual risk analysis. Mainly because the cost is unrelated to business nor government when it’s impact exceeds the ability to mitigate within a budgetable time and cost frame. Meaning, there is no acceptable risk for a disaster of this size.

Ironic that the concept of Macondo is that the usual laws of nature don’t apply there. Refering to The novel, "One Hundred Years of Solitude" and it’s fairy tale city of Macondo.

The usual laws of nature do apply! Don’t expect a miracle here. Plug the well now! Uninterrupted flow won’t float away like in the town of Macondo.

Someone mentioned a CBL (cement bond log). This is usually taken after the cement has time to completely harden. Doubt 20 hrs reported is enough and so doubt BP ran one.

Plug it. Now.

Another question you’ll have to answer if the choke is now in the riser. How come, if the velocity is so low, the riser hasn’t blown up yet. Surely the choke is keeping most of the pressure downstream. In the BOP choke case, it could handle that pressure buildup for low flow rate. But a riser could not handle the same situation. You guys proposed this situation not me. It’s up to you to prove it. What is next? Choked flow in BOP and riser simultaneously? These are theories. You can’t prove beyond a reasonable doubt that the choke is in 2 places. You’d have to be able to prove a choke in just the BOP is wrong. Can you do that?

If you can, then you have a point. But if you can’t prove 2 choke spots vs just 1, then I suggest you listen to others ideas because you have no proof they are wrong.

Go ahead, prove the BOP choke wrong now. Tell me why that is impossible. What if the BOP is choked badly? The choke in the riser will have little to no effect since the choke in the BOP chokes 10000psi and the velocity is so slow out of our first choke, that it is not sufficient for choke flow in the riser. Prove 2 separate chokes and I’ll listen.

Don’t get pissed off because I challenge you to prove your hypothesis. I want to know why a severly bad choke in the BOP is impossible.

In order to prove you are right and I am wrong, you have to disprove my theory and then prove your double choke. You can’t prove anything. You, yourself said we can’t be sure of the area in the riser kink. But you’re quick to tell me I am an idiot who doesn’t know anything about our situation. But you can’t even prove your point either, because we don’t have certain and definite information.

Maybe you are right. Maybe I’m right.

We don’t have enough information to determine that. I guess you could call it degrees of freedom.

So from now on, those morons who are telling others to ignore comments, get lost. You have no authority here.

We do not have enough information to prove anybody wrong or anybody right. So from now on, if you can’t prove someone wrong, don’t speak up. It doesn’t contribute. My situation is feasible. Your situation is feasible. As you said, we do not have enough information, so there are degrees of freedom. Proving anything with degrees of freedom requires assumptions and assumptions do not meet neccessary and sufficient conditions to prove someone wrong.

So those of you who say I have no idea what I’m talking about, well what evidence do you provide to say that without a doubt I’m wrong. None. Just name calling and telling me to lay off crack pipes. I believe that is called ad hominem. You fight my point of view by trying to discredit me rather than address the issue.

So in conclusion, sure I have been wrong because I can’t prove beyond a reasonable doubt that my theory is correct. But you have also been wrong in your attack on my position and saying my ideas are false. You didn’t provide proof with certainty that you were right and I am wrong. You took a guess that I was wrong, just like I guess I was right. I tried to provide mathematical equations to backup what I was saying along with references. But there are still degrees of freedom in my argument. I’d hope that you aren’t too conceited to admit you have the possibility of being wrong, because you surely have at least one degree of freedom in your argument or at least one assumption.

In engineering, it is not enough to just prove someone wrong. You must be able to provide a correct theory and proof of why you are correct. Disproving me isn’t the end of your journey. Disproving me might be a piece of cake because I’ve made mistakes. But you first must provide the correct theory and why you are correct, solid proof.

Hammer,

There is a crack there already, it opened after the first riser inspection by the ROVs. I have not heard if it has grown, or if it’s stable.

http://www.flickr.com/photos/uscgd8/4563035602/in/photostream/

If it’s stable, messing with the riser MAY make it worse.

If it’s growing on its own, messing with it WILL make it worse.

Any untoward vibrations on the stack or riser will cause the riser lying on the seabed to sink further in the muck, increasing the downward strain on the kinked riser section. From the picture the riser has the ball joint on the LMRP pulled over at a pretty good angle, this ball joint is bonded to a multi-ply steel reinforced rubber diaphragm, and when bent over contains a serious amount of stored energy, (it’s hard to get it to flex even with the BOPS hanging off of a joint of riser under a rolling rig).

So, what kind of proof is there that the choke is in 2 spots? None, we can’t be certain.

How do we know the choke isn’t only in the riser? The mathematical models are able to disprove that one to some extent, but there still is the assumption well pressure is very high. The mathematical models can disprove the possibility of a range well pressures for this scenario, but the well pressure is a degree of freedom.

How do we know the choke is just in the BOP? We can’t be certain. It is not impossible, but it still might not be the case.

My question to your post horizon is, why do we have to care about the crack in the riser in the kink if we are going to slice the riser off at the BOP.

Sure the crack will get worse if you mess with the riser, but in some fixing scenarios, we don’t need to worry about the rest of the riser. It could vanish after we slice it off and we wouldn’t care.

Certain consequences only apply to certain scenarios. Consequences don’t have to apply to all scenarios. The consequence and scenario should be stated together. When getting rid of the riser entirely, we have no concern if that crack grows larger. See my point.

I apologize for my previous comment. Not only was it uncalled for in this forum, but you poor folks already have a petulant child circling your ankles.

I’ll stay clear of this thread, and just watch.

hoodyz… what do you say? Let’s you and I go talk about pressure gradients over at… buymyshit.com

I believe my scenario of a second BOP can be validated for the choke in the BOP situation along with the choke in the riser choke situation. But if you have a choke in the BOP and riser, I can’t prove anything. I can talk about the probability of that being the case, but that is uncertainty.

The only way to find out is putting a pressure gauge right above the BOP. Then I can tell you with certainty if my idea will work.

as previously mentioned until a measure of the pressure in section directly above BOP and below kink is known no action there will be attempted. If you can figure out a way of doing that without changing the integrity of the riser then thats useable. nMR wont work

I mean, what is a complete list of feasibile solutions? Someone care to make a list?

What options do we have?

Try and get the current BOP working.

Cap the riser.

Second BOP.

Funnel

clotting/freezing oil

relief well

If the progress so far says anything about getting that BOP working, it would mean hopes are slim there. BP has basically stated it failed, and a fix has yet to be found there.

You’ve heard my thoughts on capping/BOP. It might be possible.

What about the rest of these options?

I guess the relief well takes a while.

Funnel doesn’t fix it, just contains the spill. We still need a fix.

Clotting is interesting and is related to capping because it is an internal cap essentially.