Posted on

May 17, 2010 by

bp complaints

New Deepwater Horizon images:

ROV attempting to activate Deepwater Horizon Blowout Preventer

Image by uscgd8

100421-G-XXXXL-_003_-_Deepwater_Horizon_fire

Image by uscgd8

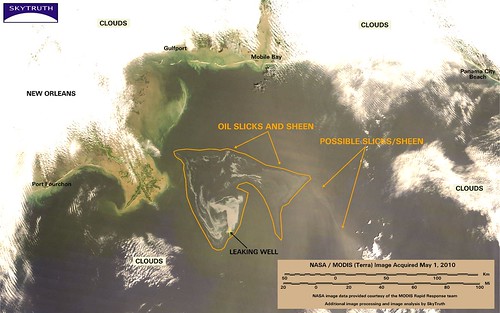

Deepwater Horizon Oil Spill – MODIS/Terra Detail (with interpretation), May 1, 2010

Image by SkyTruth

Tags: Activate, attempting, blowout, Deepwater, Horizon, preventer

Category

News

Trackback: trackback from your own site.

You guys have good ideas, but there is no pump on earth that can suck 5,000ft of head of oil or water, there are submersible pumps that can do it but the companies that make them do not stock them, again like the high pressure high load rated flex lines, they are made to order. And hauling stuff out that can’t be guaranteed to work will just end up with more junk laying on the seabed. Another problem with the idea that the oil will just float up on its own through a pipe due to water head differential will work, but not at a rate that would keep it from flowing out from under whatever umbrella, etc. that you put over the leak to capture it, have you ever seen a lava lamp? that is how oil interacts freely with water, it forms globules much like air bubbles and these globules break up into ever smaller globules on the way to the surface, if this is inside a conduit it causes a lot of friction, ie, back pressure, and this will force the oil coming it at the bottom to flow out from under the umbrella. and again this device "umbrella" will have to be very large and very heavy, the pipe used to lower it will have to be heavy as well, it will need to have a wall thickness sufficient to with stand the differential pressure between the oil inside and the heavier seawater outside. It also has to have sufficient cross sectional strength to be able to hang its own weight suspended at the surface, and the bending moment induce by wave motion and currents, this is no small force at almost a mile of pipe exposed to a 2-5 knot current. If you have ever held a stretched rubber band out of a car window and had it buzz, that is what happens to vertically suspended tubular goods in water currents, albeit at a lower frequency, the pipe will also have to be of sufficient wall thickness and diameter to withstand this force. The only article readily available that will work is marine drilling riser, and then we get back to the need for a rig or barge equipped to handle it. If they used drilling riser they could feasibly use the choke and kill lines to inject high volume high pressure air into the umbrella to air lift the oil / water mixture to the surface much like a air lift dredge works. I have seen this method used in the Arctic Ocean to drill / jet 30ft diameter wellhead cellars for offshore exploration wells, up there you have to be prepared to move a floating rig off location at any given time to avoid ice flows or bergs, these flows and bergs often times scrape the seabed, so the BOPS and wellhead have to be below seabed level, to escape damage. But keep in mind 3,000 psi air compressors don’t grown on trees either, and it would take several to supply enough volume to accomplish this mission. There would also have to be a separator barge there to handle the oil water separation. And all of this would have to be rigged to be explosion proof, because as the oil comes up the entrained gas in it will bubble out like the CO2 from soda pop.

After reading all these posts, we all recognize that this is a difficult problem and it may take numerous trial and error ideas/attemps to shut off or curtail this well. Lowering a cap or other equipment over the well would place a derrick barge in harms way. However some of the cranes on these barges can extend for quite a distance over the side of the DB (although it’s lifting capacity is greatly reduced). Any ideas on how a vessel could be placed over the well without incurring the risk of fire or explosion? It is often said "one man cannot make a difference". I find this completely false……it is usually one man who makes the difference. Keep the ideas flowing. maybe we can help ignite an idea that no one has thought of yet.

I think the leaking oil pipe should be deformed further to reduce the oil flow. OK it is a huge diameter pipe and it is not easy to deliver a hydraulic press 5000ft deep water to flatten this pipe, but if it were flattened on a few places the pressure and the flow would drop significantly.

Who knows where we can find a picture or drawing of the current situation of the well?. Who knows the exact dimensions of the equipment laying on the seabed? who has a idee about the lengths of dp and risers to be entered or cut off ?, there must be a way if oil is flowing out to enter the well bore with some kind of (mini) coil unit on a drill ship ones the rov,s have cut of a part of the riser or dp.Can the rov help to assist getting a coil into a dp on the seabed ?Is the well leaking from dp and annulus / riser ? is the bop integrity ok ? I really do not understand $ why BP / TO + government do not want share in public the technical situation as it can only help making the disaster a little smaller .But is money the only value driver in this situation to stop communicating with the rest of the world? we only want to help………………………………….

Not having any experience with the pressures and temperatures involved at the 5,000 ft. depth, I must yield to the experience of others. However, there are some points worth mentioning. A 100′ long 3/16" thick cylinder properly suspended should not tear itself apart. Thickness has nothing to do with it since weight increases proportionally to thickness. Stresses remain constant regardless of thickness. At sea level conditions the stresses on a 100 ft. long cylinder will be far below allowable limits when suspended assuming the attachments are properly designed. Regarding pumps, the discharge pressure will be high, but so will the suction pressure. The differential pressure will depend on flow rates, hose or pipe diameter and the amount of gas that is released from the oil as it rises toward the surface. Inside a 12 foot diameter cylinder, I would expect that several submersible pumps could be utilized, but I know nothing about the pumps that operate at that depth. The fact that the oil will release gas as the pressure is reduced mandates the use of submersible pumps as opposed to surface pumps. The prospect that the estimated 5,000 bpd rate of leakage may grow to 6-8 times that rate is frightening and makes it all that more essential that a soution be found to minimize the damage as soon as possible.

At the wellhead, at the first inflection tear explosion columns that had been leaked in one place. Then delete the lead ( plumbum ) slab thickness of 50 cm in size 3×3 or more, and a small explosion of a charge to drive into the hole lead stopper.

Would it not be possible to simply pour a VERY large amount of concrete over the affected leaking pipes?

I appreciate that this is a crude solution but it strikes me that it would be a quick stop gap to cut or at least drastically reduce the flow whilst the relief well is drilled.

I fear that attempting advanced ‘perfect’ solutions risks wasting time, which is the most valuable commodity in this situation.

Earlier I saw a news story of a vessel with an open bottom was being prepared to place over the BOP and collect the leakage so it could be piped to a ship above. What happened to that? I think they used something like that in the Bay of Campeche in Mexican waters years ago. Of course the bent casing, pipe, and trash must be removed first. Right now it looks like all the main players are in ringing their hands and weeping mode, not fix this fast mode. I forgot CYA mode for BP. If I kill some one driving drunk or distracted I get charged with at least manslaughter. That sounds right for the CEO of BP. 11 charges. In something like this if a leader of a company hides facts to avoid some future risk of a lawsuit that should be a crime in it self. There is a law for that called concealing evidence in a murder investigation. Remember SWAT is out there looking for evidence.

Hi PBR6, Sorry the oil is under high pressure and would just blow through the cement before it set. The currents of the Gulf would also carry away the cement without some container. If you had just the container the oil could be collected and piped to a ship on the surface. I saw on the news they are preparing just such a container. The stuff around the well must be cleared away first. A big job in a mile of water. It takes a while just to get a ROV to that depth. Sometimes an hour or more on one job I was on. We had a strong current and the ROV lost the biggest "hand" Oceaneering had when it came back up. We were over in Green Canyon in 1998 then. Anyone here remember 1998? I guess after Catrina in 2005 that was small stuff. My wife and I were in NO on Sat when they called for evacuation but she had to stay at the taping of Wheel of Fortune. I thought she was such a courtious driver. I saw the miles long line on I10 W to BR and it’ll be blowing before we get over the causway. She used to be a CSI for the FBI and later the State of Florida, like a cop she wipped to the closed right lane hit the gas and in 5 min we were where the endless line of traffic turned left onto I10W Southbound, they had the divider open so all 4 lanes could go North. Some sucker paused for a second before making his turn, We didn’t have to stop till we ate supper in Baton Rouge.

I have an idea that could be work

You take a big cylinder

Inside the cylinder you have some elastomere pillows

You set the cylinder around the the wellhead and fill the pillows

with sea water with very strong pressure so that wellhead is compressed and drowned inside somes pillows

Someone could add the picture of the wellhead model ?

So that we have consciousness of the device

When some flat ship run around, some usa companies use very big elastomer air tube that they use as trunk under for rolling he boat on the soil

you could use this tubes as pillow

You could make the converse in putting in the pipe a bar with pillows around but that is difficult to insert because of the pressure and block with oil that is a lubricant

according leak you can use small cylinder as a bracelet for pipe of well head or use a big cylinder for the whole wellhead

Here’s the bottom line. If they, meaning BP, TO, or USCG, do not have a subsea pumping operation up and running at the wellhead by the end of the day, then obviously they are incapable of handling this situation. In that case, it falls to the states affected, meaning LA, MS, AL, and FL, to at least try and immediately implement a pumping operation to mitigate the effects of this disaster on their local economies. If it doesn’t work, you move on to the next possible solution. However, not to try something along these lines at once is indefensible.

Has anyone heard of the DIFIS concept developed in Europe after the Prestige shipwreck oil spill incident, ?

http://www.difis.eu/overview.htm

The envisaged solution relies on gravity forces to channel the flux of spilt fuel towards the surface.

This is achieved by means of a light, quickly deployable flexible structure that should stay in place until the pollution threat eliminated.

The leaking fuel is collected by a kind of inverted funnel, consisting of fabric dome solidly anchored around and covering completely the wreck. The collected fuel is channelled, along with sea water, through a long, flexible riser tube (typical diameter: 1.5 – 2 meters) into a second inverted funnel close (30-50 m) to the sea surface. This second inverted funnel acts like separator and buffer reservoir, so has the function of a terminal buoy T, which keeps the whole riser line in tension and provides for a rapid periodical unloading to a shuttle tanker

More information:

http://www.marin.nl/web/show/id=88561

This funnel/dome could be constructed relative quickly, the challenge will be the riser system, but one should be looking at readily available from the shelve components to assemble the riser.

Wonder if BP has considered this option, as they have clearly started building steelstructure containment domes at wild well control. Maybe this has to do with the fact that the leakage is not taking place at the seabed but higher up in the riser, thus it makes not sense to connect a funnel/dome all the way down to the seabed,

It seems to me that publishing a clear picture of the state of things underwater is necessary in order to have a chance of getting that one golden idea that might mitigate some of the mess.

From the information available:

What ‘s the chance of having an ROV pump 12 gallons of hydraulic fluid at 3000 psi to attempt to close the BOP?

Has anyone thought of pipefreezing. This technique is used quite often to plug pipes whilst connections are made. There would be enormous difficulties, because the technique normally involves freezing a plug of water on both side of a section of pipe to be worked on.

But applying a cooling coil around the broken riser would increase the viscosity of the crude oil, slowing flow. It might then be possible to introduce some water, which could then be frozen. This would provide a temporary seal, whilst the relief well is being drilled.

Do we know why the surface BOP did not stop the flow?

Is the issue something fundamental or just the control system.

How much do we know about it’s current state.

Is it structurally intact?

Did it partially close?

Van der Velden’s description sounds plausible to me. I and others have received the following request: "Please forward all public Deepwater Horizon Response suggestions to NOAA at nickie.scillo@noaa.gov".

I believe this should be presented to them, although they may be understaffed to properly evaluate all proposals they receive.

I conclude that sealing off the leak is strictly the long term permanent solution (short of employing a nuclear device which could have serious negative ramifications). Thus the immediate priority is to capture the leaking oil to minimize the catastrophic damage it is causing to the Gulf coast. For now this should be our top priority.

Marcowellintervention,

Here is a schematic and photo of the riser where it’s bent over at the top of the BOP stack

http://www.flickr.com/photos/uscgd8/4563035602/in/photostream/

Here is a photo of a subsea BOP stack similar to the one we are dealing with

oilstatesintl.com/_filelib/ImageGallery/Products_Services…

HowAbout,

Let me enlighten you on the pressures involved here.

Water depth 5,000ft: pressure = 2223psi, temp=48deg F plus or minus a few deg.

Assuming an oil density of around 6.2ppg 5,000ft column of oil = 1622psi

deltaP at 5,000ft = 2223-1622 = 611psi, this is the external pressure your 3/16" steel pipe would have to withstand, it would not, it would collapse like a paper bag hooked to the end of a shop-vac, and this is static pressure, once you draw a vacuum inside the cylinder with pumps it becomes worse.

And the stresses involved in anchoring this cylinder in place to keep it from moving around in the current, and the vertical motion caused by surface and subsurface wave motions would tear it to pieces.

The strength of a steel cylinder is directly proportional to the wall thickness, and circumference, carbon steel @ 48deg F has a Young’s modulus of around 20kpsi a 12ft diam cylinder that is made to take a 611psi external pressure differential, with the added anchoring stresses would have to have a wall thickness of over 4-1/2 inches.

BP’s idea of using a funnel or dome shape umbrella is the practical approach, because of the hydraulics involved it would not be subject to the same external pressures, as it does not create a large diameter open ended pressure vessel like a cylinder does.

Any attempt to plug leaks in the drill pipe or riser, will not work since the drill pipe and riser are not separated by a closed annulus, if the drill pipe is plugged it just increases the flow through the riser, and visa verse, if both are plugged the riser will burst as it is only rated at 500psi internal differential pressure, and that is when it’s new and not damaged. From what little information is available, I am guessing the the well depth is around 15,000 ft below seabed, this would be a wellhead pressure of around 3,600 psi at the BOP stack if its a normally pressured well, this would burst the riser.

You have to understand this oil is not just bubbling out like a fuel leak from a sunken vessel, it is shooting out at over 160 gallons per minute, probably more, and at high pressure. This flow will increase over time as the well unloads the drilling mud from the wellbore and the leaks in the tubular goods increase in size due to erosion of the steel. A mentioned before if left unchecked the well will eventually reach full production capability of a typical GOM producing well of over 30,000 bbl/day, or for the uninitiated, this is 900gpm, or typical backyard above ground pool every 30 minutes.

There is concern that the pipe may sever and dramatically increase the flow of oil. If this occurs dramatic steps need to be taken immediately and a plan should already be in play to address this senario. Can anyone tell me why fabricating a large heavy cylindrical cap to seal the leak at the ocean floor would not work? If the only reason they would not try this is because they will not put a Derrick barge in harms way then improving the safety of the barge could be addressed. If explosive gases are densely present directly over the leaking area then forced air can be used to rapidly disperse these gases. Years ago I worked on the LCAC (air cushioned landing craft) program and five of these vessels anchored or pushing against 4 point moored barges can move a tremendous amount of air with their above water props. I would like to hear comments on why this could or would not work. It seems to be a more simple solution and the fabrication capability is here in place.

To this idea I would add if the oil pressure would jet out the sea floor after the cap was placed over the BOP/riser then the cap could contain a ‘V’ shaped plug that if positioned directly over the pipe opening it would serve as a means to seal the pipe as the sea floor was being jetted away. This would probably involve setting off a shaped charge on the pipe to provide a clean entry point for the plug. The cap weight could be accurately calculated and the Derrick barge would remain attached to the cap until the seal occurred. I have no idea what the sea floor is made of at this location but having it self seal seems feasable (not simple but feasable).

I have to confirm that the DIFIS concept has only been tested at scale model (deployment of the parachute) and has never been built/deployed in real 1:1 scale.

At least it could be helpful if the DIFIS team could share their knowledge with the developments in USA.

Much conceptual engineering has been done during the last years on this funnel concept.

Horizon37

It is obvious that I failed to properly describe my proposal. The cylinder I visualized would be approximately 12 feet in diameter and 100 feet in length with completely open ends (length to diameter ratio of about 8). The differential pressure between the outside and inside would be a small fraction of 1 psi. My guess is that a 5 psi differential might crush it, but I doubt that the differential that it would experience would be more than 1% of 5 psi. The cylinders were never envisioned to be pressure vessels. They were to serve simply as barriers to prevent the oil/water/gas mixture from escaping into the open sea.

Placing such cylinders over the leaks may not be possible and devising a suitable means of transferring the mixture to separation facilities at the surface may make this proposal impractical which is why I wish to see Van der Veldon’s proposal considered. If I were BP’s team leader on this project, I would have someone or a sub-team exploring the possibility of such a design if it came to my attention. Is there a flexible material that can be utilised to make a large funnel with, say, a 10 or 20 foot diameter riser that is strong enough to withstand the currents? I don’t know, but someone out there reading these posts may know. Will such a material be sufficiently impervious to act as a barrier? Again, I don’t know, but my personal knowledge is very limited.

ricjames1,

The area where the well is located is in the Mississippi River alluvial fan, the first 4 or 5 ft of the seabed there is about the consistency of cold oatmeal, it’s river mud. As to anchoring any surface vessel in the area, you have to remember this is 5,000 ft deep, to be an effective anchor you would need about 2-1/2 miles of anchor chain or cable, for each mooring point. Not to mention there are production pipelines all over the seabed in that area, there are 2 pipelines close by that they shut in when this happened in case the rig sank and damaged any of them, fortunately the rig missed them when it finally settled to the bottom. As mentioned before plugging the pipes is neither practical, or feasible, it would not work. And placing a cap over the whole area is impossible it’s hundreds of feet around, and would have to be about 50ft high, roughly the size of a warehouse, or really big fab shop.

All,

Deepwater Horizon Incident Unified Command has:

To submit alternative response technology, services or products please email horizonsupport@oegllc.com or call (281) 366-5511

FYI: I received this a short time ago: You may wish to "tune in"

WASHINGTON—Assistant to the President for Homeland Security John Brennan and U.S. Coast Guard Commandant Admiral Thad Allen—who was today designated National Incident Commander for the administration’s ongoing response to the BP Oil Spill—will brief media this afternoon via conference call about ongoing efforts to contain the spill and minimize associated environmental risks.

National Security Staff Chief of Staff Denis McDonough will moderate the call.

Saturday, May 1

3:30 PM EDT John Brennan and Admiral Allen will brief media on the ongoing response to the BP Oil Spill

Dial in: 800-779-2598

Password: RESPONSE (73776673)

The sharing of ideas and thoughts here is incredible. It seems like some on here are actually close to this event. Our group has been trying to get in contact with the people at BP or Horizon for 2 days now to introduce a organic catalyst that will prove to be an essential part of the clean up and remedation of the oil. We would like to get this product on the front line to help with the fight against this spill. Any assistance anyone can give would be greatly appreciated. I am happy to get more detailed information to any of you who are interested. I have already sent this to Nickie Scillo but have yet to hear back.

This product is a specially formulated bio-organic catalytic composition which greatly accelerates remediation rates, at very low relative cost compared to traditional remediation technologies.

Our solution is a biocatalytic system in a liquid concentrate form that stimulates and accelerates natural biological reactions. When combined with fresh or salt water and oxygen, the product will cause crude oil, jet fuel, diesel oil and other organic substances to rapidly decompose, eventually biodegrading them tocarbon dioxide and water as end products.

Independent laboratory studies from specialists in petroleum technology have quantified the ability this product to dramatically reduce petroleum contaminants, showing a 90% reduction in Jet-A, Diesel-2 and Heavy Duty Lube Oil within 96 hours. While treatment time required may vary dependent on conditions previously noted, the mode of action is the same. USDA Approved, 100% Biodegradable and 100% Safe to human and animal life.

arde_v@yahoo.com

It occurs to me that the proposed approx. 12′ diam X 100′ high open ended vertical cylinders employing a low head pead "pump" (e.g. a submersible cooling tower fan) and a lightweight approx. 12′ diam flexible stack might be employed to direct the oil/water/gas mix to a container at the surface.

Does anyone know how high the leakages are above the seabed ?

sheereality: I predict that your product will be in great demand during the cleanup phase which is about to begin. Did you see the message posted by Interested Engineer within the past hour?

Sheereality is this product available in large quantities. Post your information here including your company name, address, phone number and contact person. If necessary I will bring this information to BP myself as they have a location near Houma Louisiana and my home is located 15 minutes away. If you wish you can email me direct at ricjames@bellsouth.net. Provide the URL for your website.

Thanks

How About 2010: In Fact I did and made the call. Thanks!

I feel a sense of urgency here as our product should be a mandated product as it will greatly reduce the risks associated with this sort of work. I think wee need to get this too all working with the spill because open cup flash points and auto ignition temperature tests quantify the ability of this product to render petroleum products nonflammable and dramatically increase their auto ignition temperatures. The Nontoxic product alters the molecular structure that dramatically reduces flammability and the elimination of volatile organic compounds (VOCs) and their odors. These qualities would make working around the spill safer in terms of fire and potential respratory issue. Plus it works with all other methods of clean up and remediation currently available. Excuse the long winded explanation, but like I said, we’re itching to get our product to work.

HowAbout,

I take it you are thinking of having this cylinder suspended at the surface?

this too would be impractical, as the area where the plume reaches the surface is several thousand feet across and varies in location depending on current, tide and wind conditions. In other words it’s a constantly moving target. A large diameter flexible hose that would reach the depths we are dealing with does not exist. High Pressure High Static load flex does, it’s a normal type of production riser for floating production platforms, but are only 3-6" ID and up to 18" OD depending on the depth and pressure that is being dealt with. And I reiterate, the companies that make these flex lines do not stock them, they are custom made for each order, because they are VERY expensive and usually ordered a year or more in advance of the project actual starting. An 800ft reel of 15,000psi rated 3" ID flex is about 3million bucks, and weighs about 15lbs per foot, and the larger the ID the thicker the wall, hence the exponentially larger the OD and the more $ and weight per foot. These risers must be designed and built for each given set of criteria, they have to be able to suspend their own weight plus the weight of the product in them, and the movement / strain forces they will be subject to. An example of this would be if you tried to pickup 5,000 ft of empty garden hose you would not get all of it off the ground before it was torn in two from its own weight, let alone if it was full of water.

These seem like workable pumping plans. Definitely moving in the right direction here – I’m sensing some momentum. Keep pushing forward because these ideas need to be acted on right away.

Also, don’t get bogged down on the pipe engineering because there are many nearby rigs with thousands of feet of suitable pipe and other materials and eqiupment.

To reiterate, these folks need to start putting pipe in the water now.

This thing will need to be put together on the fly.

Thanks horizon 37 for the picture

oilstatesintl.com/_filelib/ImageGallery/Products_Services…

We can’t unscrew all the BOP and knock over ?

So that we have just the head the well

After we screw an open tap with big hole for avoid pressure problem during setting and after we close the tap

First Idea

http://www.PROinvention.com/BP-drawer.jpg

a simple drawing that you push smoothly above the hole so that pressure is not a problem

Someone know how are the damages of the BOP ?

I agree with concerned citzen . We should be on the move . i dont want to make any more of a mess than we have . Thats why i suggest something all ready built with the pumps on top, open bottom so we dont have to worry about the pressure or vacumm .It doesnt have to be shaped like a funnel just a vessel to collect the oil into so what if we suck a little water also . Thepumps should be hydraulicly or electrically ran . I dont know how far the head pressure they could pump . It sounds like about 9000 gph is what it is leaking so it would take more than one pump. Correct me if im wrong Yes it would have to be supported from the surface .Its not long term just a quick fix till we can stop the leak .

Second idea

http://www.PROinvention.com/BP-pillow.jpg

a cylinder with elastomer pillows inside that you fill with seawater with big pressure

you can put it around the pipe and fill the pillows so that pressure is not a problem for setting

cylinder can be in 2 part that you put together with screw around the pipe and after you fill the pillows

I wanted to said for the 2 parts cylinder

You close the cylinder around the pipe where there is not leak, after you slide the assembler cylinder over the leak and then fill the pillow

Hountsi,

The BOPs are the only thing keeping the well from going to a full subsea blowout. And they are damaged and still have a few thousand feet of damaged riser attached to them. And even if they could be removed, it would cause a bigger mess than is presently going on.

Maybe the US Navy can get one of their secret weapons or a sub down there to stop the flow!

Hountsi the oil would probably cut through the elastimer bags as they were being inflated in the cylinder.

Ok, If I understand (I’m french)

The oil blowout trough the end of a severed pipe

We have to find a solution for closing this end of broken pipe

It exists very strong elastomer

When some flat ship run around, some usa companies use very big elastomer air tube that they use as trunk under for rolling he boat on the soil

they are very robust

you could use this tubes as pillow

Third Solution

http://www.PROinvention.com/BP-toric-roller.jpg

A part of pipe with few conical shape

Inside a toric seal that work as roller

When new pipe is closed, pressure push the pipe and seal roll on the slope so that seal is compressed

Horizon 37

I must apologize for the lack of clarity in my posts. One reason is that I posted my thoughts serially as the concept was developing in my head and after reading other posts.

Essentially it goes like this from the seabed up:

Sitting on the seabed are vertically mounted 12′ diam x 100′ high cylinders fabricated from 3/16" steel plate. Cutouts are made in the bottom of the cylinder to accomodate obstructions. The cylinders are positioned such that a leak source is inside each cylinder near its centerline and near its bottom end.

A low head "pump" (similar to a submersible cooling tower fan), located near the top of the cylinder propels the oil/water/gas mixture upward into a 12′ diameter flexible lightweight "stack" acting as a barrier to prevent the mixture combining with the sea water. The rate of propulsion would be just sufficient to keep oil from leaking out of the bottom of the cylinder. The stack would serve only as a barrier and the pressure differential inside and outside the "stack" would be essentially zero.

On the surface an armada of barges would form a "sealed" circular or rectangular containment area preventing the mix from mixing with the sea water. The stacks would discharge into the containment area and the contents of the containment area would then be transferred to tankers for further transfer to processing facilities.

Obstructions at the leak locations may make this proposal unworkable, as may the unavailaility of suitable pumps, exotic material for fabricating relatively impermeable lightweight flexible stacks, etc. Also I have not yet come up with a means for handling the highly flammable gas that would arrive at the containment area with the oil and water.

With regard to the "pumps", a compressed air or high pressure water operated venturi may do the job.

I hope this clarifies what I had in mind. As this concept has evolved in my mind over the past 36 hours I now fail to see why the cylinders should be any higher than 30′ or less.

If the seal is not good positioned, the pressure of oil will push the seal and become fitted