Posted on

May 17, 2010 by

bp complaints

New Deepwater Horizon images:

ROV attempting to activate Deepwater Horizon Blowout Preventer

Image by uscgd8

100421-G-XXXXL-_003_-_Deepwater_Horizon_fire

Image by uscgd8

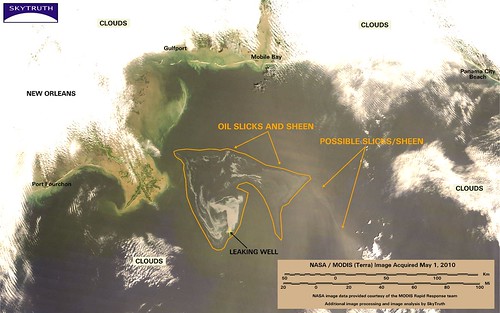

Deepwater Horizon Oil Spill – MODIS/Terra Detail (with interpretation), May 1, 2010

Image by SkyTruth

Tags: Activate, attempting, blowout, Deepwater, Horizon, preventer

Category

News

Trackback: trackback from your own site.

Horizon,

The hydrates formed throughout the inside of the cofferdam and completely plugged the opening at the top before the piping to the surface was even connected. The hydrates formed much more quickly and in a much greater quantity than they anticipated. The hydrates are making the structure buoyant. BP thought the size of the opening at the top would prevent hydrate formation on the way down, but were way off. It is my understanding that they have all but written off the cofferdams at this point and are basically moving on to the next plan which is the "junk shot" and topkill.

Oceangopher,

"2. Can someone here describe the procedure/process of installing casing in the hole? Does it line the entire hole, or only the unstable geology above the bedrock? Is it all the same diameter? Is it driven (hammered) down the hole? How to get one section past another? How to get a drill bit whose diameter is greater than the casing, up/down thru it? I’ve searched the web and can’t find an explanation."

Very Basic Rudimentary Explanation: When drilling the pressure in the wellbore must be greater than the formation pore pressure, but less than the formation fracture pressure. Basically you have a drilling window between pore pressure and fracture gradient (otherwise you risk a blowout or collapsed hole). As you drill further down, denser mud is needed to overcome the formation pore pressures of deeper zones. In order to maintain control of the deeper zones without damaging shallower zones, casing must be set to seal off the upper zones.

So you start with the largest size drill bit and drill down unti the hydrostatic pressure from your column of mud is about to overcome the fracture gradient. At this point you stop drilling and set conductor casing (runs from surface to first casing point) You then switch to a smaller drill bit and drill down until you reach the fracture gradient again, pull out and set your surface casing (smaller diameter than the conductor csg). Switch drill bits and repeat with intermediate csgs. Finally once you hit TD, you set the production csg (smallest casing) down to your deepest producing zone. This casing will run from the wellhead all the way down to the producing zone. Finsih completion and start producing.

A casing shoe guides the casing down the well bore to the bottom. The casing is hung from the casing hanger (a subassembly of the wellhead) and cemented into place.

I havnt read that yet. I thought they said the riser would burst ?

TAMUpete.

Thankyou. Makes perfect sense now. I never considered the increasing pore pressures and the differential pressures. Excellent explanation.

I did find a web site discussing expandable casing:

http://www.thefabricator.com/article/tubepipefabrication/expandi...

How foolish. There’s no hydraulic fluid pressure to power the hydraulic rams 😉

Sally-ho, brave hydrocarbon-fluids! The surface awaits, and all the livers of the ingrates.

Oceangopher You are right about the change of state regardless but its how to handle the volume of gas, or crystal at depth. The current 100ton box did not separate the oil from the hydrate at depth. If this can be accomplished,—– BP is betting on a bigger box now. We will see some improvement in possibility. At 5000ft H2O, the pressure is just north of 2100psi. The temp is close to 48degrees Fahrenheit.

I still wonder about the need for deepwater wells. Why not drill from a shore based rig or a proven shallow water one and pay the tax to the state you are raping instead of trying to save a few bucks. What Louisiana would gain in taxes would have more then covered this fiasco The ability to drill fifty miles out from shore in a directional rig is more then proven so what are we doing trying to fix a problem a mile down………

I’m wondering about a couple of things…

First, enough methane hydrates formed in under 10 hours to start making a 100 ton concrete and steel box buoyant! Holy schmackerals, this is a gassy well, eh, what?

Second, are those same hydrates forming inside the collapsed riser? Is it just the cooling effect when they hit the open sea floor that is suddenly making them all coalesce? Or should we be worrying about a plugged drill pipe that just might explode?

Third, obviously, they couldn’t have the riser pipe attached to the caisson as they lowered it into place, and have a hope of keeping it on target with a mile of steel overhead, subject to currents and ungodly amounts of inertia. But they need that warm (or better yet, hot) water down there.

Can they put in a flexible hose, with a few floats to make it buoyancy-neutral, and anchored to the bottom on something really heavy? Pushing steam from the surface (or as hot a water as they can get) to keep the caisson clear while it settles into the muck and until just before they attach the main pipe? Which is supposed to be a double unit that pushes warm surface water down the outside while the oil and hydrates rise up the center.

Or is this well just too gassy to manage?

Gas hydrates are more prevalent then oil deposits.

Good explanations here about methane hydrate:

http://www.llnl.gov/str/Durham.html

en.wikipedia.org/wiki/Methane_clathrate

marine.usgs.gov/fact-sheets/gas-hydrates/title.html

Interesting stuff!

Oceangopher nice job on the info. As you can see this stuff is hard to work with. I hope the increase in collector size helps with the formation problem BP is currently trying to deal with. Nice day at the beach here in St Pete Fl, hope the beach looks like this beyond the next few weeks.

optimusnine

It’s not too hard to follow. I spent 30 years in military oceanography. Spent a lot of time on oceanographic vessels putting stuff in the water and hoping it would all come back. Been to many OTC and MTS conferences. I was familiar with the technology, but not the techniques, procedures and details. This little forum is a treasure trove of imformation. Wish I could find a few more forums like this.

I’m in Pass Christian, MS and everyone here is in a panic over this. We still haven’t recovered from Katrina. Fishing industry is just starting to stabilize and now this. But, so far, it has stayed off shore.

kenbob

The well has a gas oil ratio of 3000

"Gas Oil ratio of 3000."

I didn’t get any density figures for hydrates out of the link–they may have been there and I might of have missed them.

So let’s assume a very generous density of half of that of water. This is almost assuredly too low. The low figure will make my point harder to prove.

Hundred ton caisson, reportedly made buoyant in 10 hours. To make it buoyant, gotta have at least 100 tons of half-density hydrates attached to it (I’m assuming it didn’t actually float off–just didn’t sit down on the leak like it was supposed to).

Well is supposed to be leaking 5000 barrels of oil a day. Oil is lighter than water, so lets give it a nice round figure of 7lbs per gallon. 42 gallons in a barrel. And remember, only ~85% of the oil is actually leaking at this spot.

5000 x 42 x 7 = 1,470,000 lbs of oil every 24 hours. 61,250 lbs per hour.

Amount required to make caisson somewhat buoyant, 200,000 in 10 hours. 20,000 per hour.

Assuming every bit of methane hydrate that came out of the pipe stuck in that caisson and not a bit of it went out the open top, we’re talking at least a third of what is coming out of that pipe being methane hydrates.

And that’s assuming every bit is sticking, and that they are half the density of water, both of which assumptions are highly biased towards needing less hydrates, not more.

Possible wild cards are the inherent buoyant of the concrete and steel caisson, but concrete and steel aren’t known for buoyancy and an open top isn’t going to hold air (which would become liquid at depth anyway, and not provide any lift).

There is a very great deal of gas coming off this well, or we are being told stuff that isn’t true.

Or, possibly, I am completely misunderstanding something. I welcome an explanation.

At the very least, there should be some concern about the pipe getting plugged by hydrates, and bursting the non-rated (and as has been noted, bent and weakened) portions of the drill pipe. Natural gas pipelines sometimes have plugging problems with hydrate formation. At the kinds of volume we appear to be talking about, I am astonished if there is not concern about the drill pipe and weakened Riser.

(My apologies if I use the wrong pipe terms. I assume there is a strong, high-pressure-rated section of pipe coming out of BOP. I refer to that as the Risor. I assume there is a further section of normal drill pipe, rated at about 600PSI, that takes over after the reinforced section ends. I assume that at the main leak, which is some 1500 feet away from the BOP as the pipe lays, is normal 600PSI drill pipe).

Where I am leading with all this is twofold. First, I’m distressed, and have been distressed since April 20th with the lack of real information we have been getting. This site has been a godsend for me in that regard, even though trying to understand some of the discussion makes my brain hurt.

Either we have something pretty unusual going on down at the leak, or we aren’t getting an accurate report of what is going on. Quite possibly both.

With talk of attempting a topkill, which folks here have pointed out has the potential to create a tenfold increase in the spill if it fails, I am not comforted by non-existent or clearly deficient reporting of the causes and conditions surrounding this disaster.

BP, in particular, is not to be trusted. I worry about how much the Coast Guard is in the loop, and how much they are trusting what BP tells them.

If they use my suggestion on how to plug the leak there should be little chance of the riser bursting. it is hard to determine from what I`ve heard so far exactly what their plan is.

some how I have this bad feeling they will screw it up lol. My old, If you want it done right , do it yourself work ethic coming back, that’s how I worked myself into an early retirement lol.

Is the control cable for the BOP part of the riser or separate?

If the control cable is separate, can they haul the platform end back to the surface. It seems if they haul from the platform end and very carefully shepard it lifting from the floor with an ROV, then there is a chance of getting it up untangled.

If they do get the end high enough to connect, can they use it to power up the electronics and get a glimpse of the state?

How about the pipe for providing pressure to power the BOP?

If it’s part of the riser, maybe they can figure out another way to provide power if the glimpse says it might be useful.

It sure would be nice to have a clear picture of the construction of the BOP and whatever they know for sure about it’s state before and after the event.

I wonder what happens to the BOP if it just site there. Will it keep pressure on the valve closing rams until the relief well takes over? Is there any information in the electronics that will get lost before the BOP gets retrieved?

When this is over, this thing needs to end up in a museum for public display.

It also needs a slight redesign, it should have fairly easily been able to have a few inexpensive backups that may have averted the oil leakage.

Over a week ago I suggested that they start injecting compressed air around the leak(s) an let the rising gas bubbles increase the buoyancy of the oil and funnel it to a specific location at the surface where it can be confined, skimmed and collected. Does anyone know why they haven’t tried this? A large volume of compressed air will channel the oil to the surface instead of allowing it to disperse with the ocean currents.

"Does anyone know why they haven’t tried this? A large volume of compressed air will channel the oil to the surface instead of allowing it to disperse with the ocean currents."

Air a mile down in the sea is air is compressed into liquid form, and most gases are neutral buoyancy or slightly heavier. So they won’t provide any lift.

The methane in the oil is already outgassing as it approaches the surface, which would provide most of the benefit you seek with your idea.

Also, you would have to deal with an increased tendency for the oil to spread out if you increased the overall upwelling from the depths.

Finally, they’re mixing dispersant into the oil column at the source, which they seem pretty happy about. Your idea, if it worked, would limit the benefit of the deepsea mixing.

That’s pretty much what I figured. The air flotation idea was just too simple and cheap to have not been previously thought of.

kenbob,

Air is not liquid at 2,200psi, to liquefy air at 2,200psi it has to be chilled to less than -220degF it’s only 42-48degF at the seabed. Remember gas heats as it is compressed.

2,200psi air compressors are available but they are very low volume, (used for filling air tanks for scuba and BA sets), to be of any effect to air lifting oil at this flow rate they would need to cover a barge deck with them.

However there are nitrogen and CO2 pumping units used everyday in the oilfield and industrial work, that could provide the volume.

What they need to do is have the system ready to start flowing oil to the surface before they lower it over the leak, that way the cofferdam is not just setting there plugging itself up.

The idea I sent into BP was to use regular marine drilling riser, and pump hot water or steam down one choke or kill line to heat the riser and the top of the cofferdam and nitrogen or CO2 down the other for lift.

Since there are flotation collars on the riser it has an insulating effect to retain the heat of the steam or hot water and the hot gas pumped down the lines, and the oil rising up to the surface.

kenbobb: I, too would like to know all the details you asked about earlier, but I wonder why any of us (on this forum and others) would expect BP to release all that kind of technical information. I can assure you they have very good engineers working on the problem, and just because they aren’t giving us all the information we would like doesn’t mean anything.

I was thinking the cofferdam needs to be retro-fitted with two large diameter valves than can be left open while the structure is being placed over the leak, the riser is being connected, and the treated (or heated) water is being circulated. This would allow the leak to flow until the full capture system is on-line, at which time the bypass/relief valves would be closed. They could also be used as "throttle valves" if the system tries to ice up again; relieve some of the flow until the heated fluids have a chance to de-ice. Just an idea, but it seems workable.

kenbob

it sure is a very gasey well 3000 gas to oil ratio confirmed by bp, the lower density does provide the lift

hydrates wont form in riser as no water in there to source for reaction.

maybe the cofferdam could have its top sheared off and put in place with the hydrate all rising untill lid come down with riser attached to surface with no seawater in riser but a substance that contains low water volume. The lid with riser attached could be lowered on top with substance inside dumped onto pipe. A valve down the bottom of the cofferdam could absord this flush and vent to the sea not putting pressure on pipe. This could then be closed by rov on station there as surface pumping resumed. Lid would be lashed down by rov too but riser weight on lid would help with that

Reducing the height and width of cofferdam would reduce volume of seawater available to form the hydrate

"kenbobb: I, too would like to know all the details you asked about earlier, but I wonder why any of us (on this forum and others) would expect BP to release all that kind of technical information. "

Maybe it is just me, but after a disaster of this magnitude, I think BP should be compelled to share any and all information they have.

I would think the Coast Guard already has the authority to do this.

If BP sits on information, I think it should certainly impact the question of punitive damages. Anybody who blows a well in American waters should figure they’ve forfeited their ability to conceal their dirty laundry.

Model graphics of semis and components.

http://www.ciaas.no/images/AWILCO_RIGSPEC_PP.jpg

A field development.

http://www.ciaas.no/temp/images/bigimages/EKOFISK_LANDCAPE1.jpg

Sea floor storage.

http://www.ciaas.no/temp/images/bigimages/200909ottsubseabagbig2...

http://www.ciaas.no/temp/images/bigimages/EKOFISK_LANDCAPE2.jpg

optimusnine: Last night you asked: “I still wonder about the need for deepwater wells. Why not drill from a shore based rig … and pay the tax to the state … instead of trying to save a few bucks. …. The ability to drill fifty miles out from shore in a directional rig is more then proven …"

We’re drilling out there because the big reservoirs are offshore – the big ones on land have already been produced. The oil companies are still looking on land, but they’re not finding the big reservoirs. Alternative energy sources are the subject for another discussion. Paying state taxes would be minimal compared to the costs of deepwater drilling, and the companies would be glad to pay them instead, IF they could drill directionally from shore. But the truth of the matter is, fifty miles is WAY beyond the capability of directional drilling. Remember also that many of the deepwater prospects are over 200 miles from shore. Deepwater drilling with rigs like the Horizon is the only way to produce these formations at present. Where did you get your information that fifty miles is within present drilling capabilities?

They should have lowered the cofferdam upside-down.

To all,

New info on topkill. BP exec says they have not tried topkill because they are gathering diagnostic information. He says BP is tapping into pressure tranducers to get pressure information. Also says that the top kill would be done through the choke and kill lines.

Also says they are working on modifying the smaller Macondome and could try to place it over the leak early next week.

Horizon said: "The idea I sent into BP was to use regular marine drilling riser, and pump hot water or steam down one choke or kill line to heat the riser and the top of the cofferdam and nitrogen or CO2 down the other for lift. Since there are flotation collars on the riser it has an insulating effect to retain the heat of the steam or hot water and the hot gas pumped down the lines, and the oil rising up to the surface."

Exactly my thoughts … probably doesn’t even need to be steam – wouldn’t surface seawater even maybe be warm enough? And the CO2 or similar "lifting" gas makes a lotta sense as well

BTW – I see from the side view pic of the riser stack at the kink that the drawings we have seen that show a stright section above the wellhead/BOP stack are not correct – there is nothing to clamp onto

I realize this sin’t the same BOP:

image.made-in-china.com/2f0j00oeCackQJZfun/BOP-Blowout-Pr…

But why couldn’t they go to one of the BOP’s in the stack and pull off one end – remove the shear ram – and gain access to the well thru it? I understand you run risk of ending up with well pressure but it seems clear that there is some attenuation provided by BOP’s or the riser would have burst already?

And for the future it would seem a simple solution would be that one of the BOP’s should be a hole cutter able to cut anyting put down the well, backed up by a ram to push out debris and close the stack?

220mph,

ROVs can’t remove a BOP bonnet, and even if they could it would open up a 24"w X 12"h hole in the BOPs open to the well. You can think of BOP rams as a 2 piece gate valve.

Here is a pic of what these shear rams look like. they about 24"wide x 12"thick.

Here is a cutaway of the type TL BOP.

tmm16:

With regards to your assurance that they certainly have good engineers working on the problem. I agree, but I guess they had good engineers when the well got away from them, and when the BOP failed, and when the platform sank, and now when the leak is continuing after how many days. It seem like at some point, it wouldn’t hurt to have another source of ideas.

But an honest desire for other ideas requires a willingness to release details of the problem, which they clearly are not doing. This seems supprising given that they have the Internet at their disposal.

This may backfire in a case this size. The information is likely to come out eventually, anyway. Then they will have to defend against Monday morning quarter backs. For the present, the choice of strategy appears to be theirs. It is interesting that the attempt to reduce liability may actually increase it if it puts the Gulf more at risk.

I’m sure in addition to the good engineers, they also have good lawyers.

AIEngineer,

If you have ever been involved in an industrial accident, the first thing that happens afterwords is your lawyers tell you to shut up and don’t give out details to anyone, especially the press.

The press is not only infamous for distorting the details, but are even more notorious for totally screwing them up, reporters are not drilling hands and have no clue about what goes on on a rig, and being reporters what they don’t know or understand, they make up, or get information from less than credible sources.

I have read so many articles in papers and seen reports on TV that are completely ignorant, I have pretty much just been ignoring them anymore.

"I have read so many articles in papers and seen reports on TV that are completely ignorant, I have pretty much just been ignoring them anymore."

This is true, and I am certain you are also correct about what the lawyers have told them.

My wish is that the Coast Guard would start giving more detailed briefings.

And even if they won’t let the crew talk (and they won’t–the one guy who did any talking took considerable pains to preserve his anonymity), they should be forced to start revealing more details about what is actually happening on the sea floor now.

That might help to make the news stories somewhat less stupid.

Somewhat. I have a degree in Journalism. I have no illusions about the state of our Mediacracy.

After I graduated, I went to work in a factory doing technical writing. Not glamorous, but I at least felt like I was doing something worthwhile.

kenbob,

From what I can gather from folks that are working on the response, the USCG has pretty much left the subsea stuff to Transocean and BP, who have called in every well intervention specialist that will answer the call, there are literally 1,000s of engineers and blowout specialists working on this problem.

The USCG primarily is focusing on environmental impact, as their knowledge, experience and expertise is on top of the water, not under it. And most definitely it’s not in the business of subsea blowouts and subsea drilling.

BP said the GOR is 3000 to 1, so 5000 bbls/d / 6.28 = 796 m3/d

796 m3/d X 3000 = 2388535 m3/d gas or 2388 E3M3/d / 28.2 = 84.7 mmcf so basically 85 million standard cubic feet per day

that is a lot of gas, no wonder it hydrated off

Transocean CEO, Steven Newman testifies before the Committee on Energy and Natural Resources, United States Senate about Deepwater Horizon Rig Explosion…

http://www.huffingtonpost.com/2010/05/10/transocean-deepwater-ho...

"At this point, drilling mud was no longer being used as a means of reservoir pressure containment; the cement and the casing were the barriers controlling pressure from the reservoir. Indeed, at the time of the explosion, the rig crew, at the direction of the Operator, was in the process of displacing drilling mud and replacing it with sea water."

"For that reason, the one thing we know with certainty is that on the evening of April 20, there was a sudden, catastrophic failure of the cement, the casing, or both. Therein lies the root cause of this occurrence; without a disastrous failure of one of those elements, the explosion could not have occurred. It is also clear that the drill crew had very little (if any) time to react. The explosions were almost instantaneous."

Why on earth would the BP engineer elect to replace the mud with seawater? Seawater under hydrostatic pressure, does not have the density and cannot maintain the required pressure to control this well.

It sounds like the reservoir pressure blew everything up the hole, including the cement plugs.

Someone really screwed the pooch on this.

"The attention now being given to the BOPs in this case is somewhat ironic because at the time of the explosion, the drilling process was complete. The well had been sealed with casing and cement, and within a few days, the BOPs would have been removed. At this point, the well barriers – the cementing and the casing – were responsible for controlling any pressure from the reservoir."

If the well was complete, casing in place and cemented, cement plugs in place, why would there still be drill pipe in the hole to jam up the BOP? If there really are tools in the BOP?

Albertatech,

Your conversion factor is in error, the BP quote was in scf/bbl not scf of gas to scf oil. To convert bbls to ft3 multiply the bbls x 5.6146. In this case 5,000 x 5.6146 = 28,073 scf/day flow, which equates to 15,000,000 scf/day of gas at atmospheric pressure with a cut of 3,000 scf/bbl, that is a small amount of gas. It is not a very high gas cut, especially for light Gulf crude, I have seen as high a 40,000 scf/bbl on crude oil wells, and as high as 120,000 scf/bbl on condensate wells.

The BP spokesman considers it gassy

"It’s a fairly gassy oil – it has a gas-to-oil ratio of about 3000 – so a major challenge for at least the first 2000 feet is hydrate management. It’s at those first couple of thousand feet where the risk of gas hydrate formation is the highest"

http://www.upstreamonline.com/live/article214352.ece?WT.mc_id=re...

if it was the casing that broke off and the concretes in the BOP may be more will do so slowly blocking it

http://www.foxnews.com/us/2010/05/11/oil-firms-tie-rig-blast-plug/

Halliburton maintains they did not set cement plugs.

Casing cement was only 20hrs done with retardants to eliminate early setting.

Packoff set bellow …

Riser flushed to seawater.

This is causing some anxiety.

If this is the case then maybe they could have opened the stack after the full setting time required and the cement would have held at the bottom of the casing.

When they say the cement job was completed 20 hours before the blowout,

does that mean they finished pumping cement 20 hours before,

or that the cement had had sufficient setting time 20 hours before,

or something else?

If it was the first, then is it likely that a hanger or production liner is blocking the shear rams?

PS: H37: yes I agree the state of the fourth estate has room for improvement. Sometimes it seem like some of the best TV news is from the commedians.

Fortunately we have the Internet.

Cement process was completed 20 hours prior. The noted minimal time for setting was 24 hours.

Some of the reported first hand accounts note a loud thump or bang followed by a second bang. Not sure that could be a transmitted failure downhole to the surface through the riser.

Could the packoff been under pressure and let go releasing the gas blow?

Would the packer be hung up in the BOP rams and nor allow the sheering? I do not know the construction of a 9" packer.

My impression is that cementing isn’t done until there are two plugs in place, with mud in between them.

I get differing impressions of where the crew was in this process depending on the source. One reason a nice news conference with the responsible parties answering questions about exactly where they were in the process, and providing a written timeline of events leading up to the catastrophe would be very welcome.

It seems pretty certain they were pumping mud out of the pipe and into the barge at the time of the accident. It also seems certain that having that mud down there would have at least slowed the pace of the kick, even if it wouldn’t have necessarily stopped it.

This cone of silence from BP is very frustrating. This is where I think the Coast Guard or MMS could step in and say, "Alright, I know you’re busy on with the well. But we need released to the public the schedule of the last three days on that well. In writing, and accurate enough that you will answer to it in court."

If BP claims it can’t tell the public what the work schedule was leading up to the accident, what business do they have being out in the Gulf drilling? If they don’t even track what their $500,000/day rigs are doing in the normal course of business, how can we trust them in such a perilous environment?

This proves sometimes why you dont listen to the engineer. I do think an informative news brief would be good that way it cuts the bs people that want to talk and look important…. Proper info usually shuts them up. But im not a a dazzler with bs just the one of the many that gets it done.

kenbobb,

I don’t know how familiar you are with rig data collection, but unless BP was willing to pay for real time data acquisition via satellite, all of the information will have to come from witnesses that were on the rig. Daily drilling reports are traditionally transmitted to shore in the mornings, they contain the previous days and nights activities as required by the operator and IADC/API, these are usually pretty brief faxes, or these days email, the hard copies are are sent in on the next available chopper with the rigs mail.

In this case all of the reports leading up to the fire since the last faxes to town, and chopper from the rig are still on the rig under 5,000ft of water melting away, if they didn’t get burned up in the fire. Could the personnel leaving the rig when it was being evacuated grabbed up the rig/ships log book and the IADC drilling report pads? possibly but in a state of emergency they could well have been left behind.

And as far as anyone compelling BP or any other private company to release information to the public, it can’t be done, if they don’t want to release it they won’t, and no court or other government agency can force them to. The only time this information might be released involuntarily is during the discovery process in a trial, and even then it may not be made available to the public. We still have a 5th Amendment under the US Constitution, and an FOIA request does not apply to private companies or individuals, only to government entities.

txgho1911,

This is not a land rig or jack-up rig doing a platform well, the seals for the casing hangers in the wellhead are integral to the hanger, (they are made onto it) and as I have iterated several times here, once these hangers are latched in they can’t come out, to get them out after the lock-down ring is put in you have to use a overshot mill to mill the ring and seal assembly/latch-downs out, the latch-downs and lock-downs are ratchet type teeth, they only go one way. They usually don’t do this, when they abandon a subsea well permanently, they cut the casings with a casing cutter or shaped explosive charges below the mud line and pull the whole mess to the surface to be disassembled on shore. As far as loud bangs and what not, that was probably caused by the seawater blowing the rotary bushings out of the rotary table and them landing somewhere on the rig or the water column shooting out of the rotary lifted the top drive or blocks, and when the water switched to gas those pieces of equipment dropped again.

And it could also have been caused by the drill pipe being squirted out of the hole and lifting the top drive or kelly whichever they had hooked up to pump the seawater and it dropping again.

Could the 7" liner have shot up the hole, it’s possible but not probable, the slips on the hanger have teeth that are constructed to resist movement from both upwards and downwards stress, these slips and pack-off are set by hydraulic pressure on a ball that gets dropped after the cement job is finished and the liner is pressure tested internally by the rig pumps or cementing unit, whichever does the cement displacement, on liners it is almost always the cement unit as the displacement volumes and pump rates are usually low, and the volumes can be more accurately measured, because the job is done through drill pipe all the way to surface. And the annular space between the liner is small.

Here is a link to a typical liner hanger.

http://www.alibaba.com/product-gs/257541973/Hydraulic_Liner_hang...

‘Daily drilling reports are traditionally transmitted to shore in the mornings, they contain the previous days and nights activities as required by the operator and IADC/API, these are usually pretty brief faxes, or these days email, the hard copies are are sent in on the next available chopper with the rigs mail."

That’s all I was talking about. I don’t expect anyone to stop on the way out to grab paperwork.

But obviously folks on shore are getting daily reports on rig status and work progress. As well as a daily plan for work ("today we plan to drill 1000 feet and prepare rotate the tires"). Those reports would have to be going ashore in a timely fashion in order to allow for basic material planning, and to know when to send out barges loaded with various supplies.

So it should be very easy to provide a basic report on what happened the couple of days before the accident, and what was planned to be done the day of the accident.

As far as being able, or not able, to compel the information release, one might think BP would be trying very hard at this point to please regulators and perhaps even the general public. A simple timeline of known events (and the last couple minutes on the rig are certainly going to have multiple interpretations) would do a great deal to helping those who have a clue understand what was going on, and to dispel some of the speculative BS that inevitably fills any information vacuum.

I’ve been frustrated since day one with not knowing what the heck is going on. In order for me, as a citizen, to have any comfort with further drilling in the Gulf, I want to know that future incidents will be more transparent.

Offshore drilling is a privilege, not a right.

Does any one have any idea if Transocean will ever try to recover/salvage this rig as part of the investigation or mabe salvege/repair?